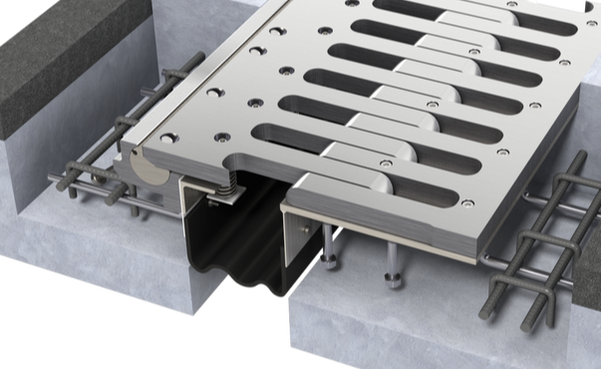

BAS®Long-Run Expansion Joint System

The BAS®Long-Run Expansion Joint System has been developed as an innovative way to combat durability issues surrounding existing expansion joint technology, specifically surrounding the finger joint type systems. Previously to the BAS®Long-Run system, a finger joint was often considered as a consumable item, not really expected to last like a Modular Expansion Joint System does. The BAS®Long-Run Expansion Joint system challenges this perception, and has changed a Finger Joint profile into being considered a permanent component of any bridge structure.

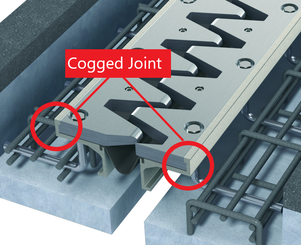

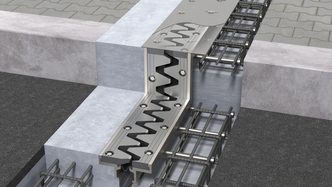

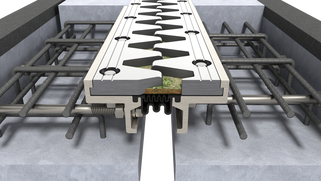

BAS® Cogged Joint Technology

|

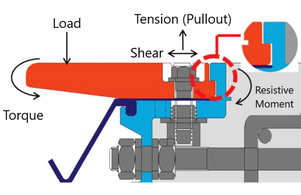

Our uniquely engineered "cogged joint" technology is the backbone to our design. This engineered feature ensures the hold down bolts are protected from tension forces from cantilevered systems, along with shear forces cause by tyre traffic traversing the joint. The most common failure in bridge joints is spalling of the block-out concrete. This is often a result from dynamic forces experienced from vehicles traveling over the joint area. Our system protects both the surrounding concrete, and the bolts from these forces, by directing these forces away from the bolt, into the interface of the dual plate design, therefor significantly reducing the risk of failures in this area.

|

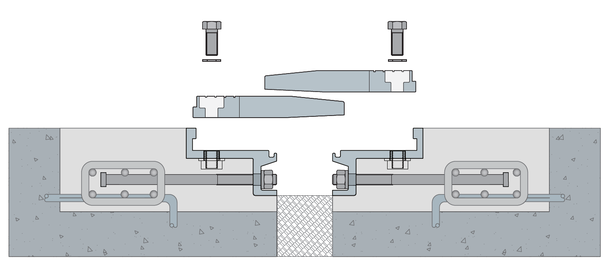

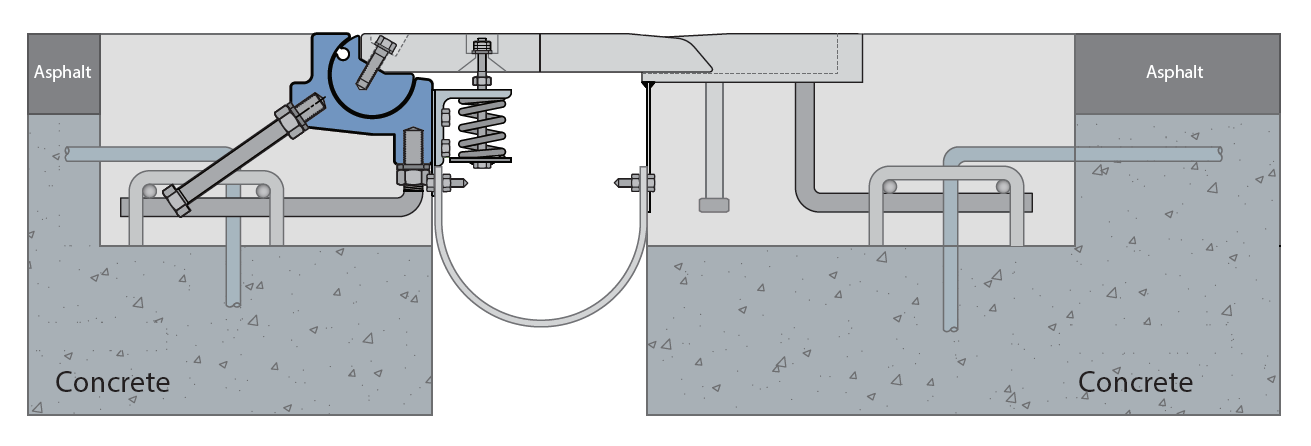

BAS®Earthquake Resistant Joint - Finger Joint catering to X, Y and Z axis

|

Another development we have achieved in this range, is the BAS®Earthquake-Resistant expansion joint system (BAS®ERJ). This system has the ability to move on all three axes (X, Y, Z) during seismic events. Its a unique finger joint design, but yet able to withstand movement on all axis, including transverse and vertical! The BAS®ERJ ensures the roadway is usable after the seismic event stops (when used with a damper and bearing). Because it is a finger joint profile, it provides a continuous surface for the tyres and resulting in a smooth ride, helping reduce road noise, and makes for a more comfortable experience for vehicles.

|

|

By specifying the correct BAS®ERJ system in conjunction with dampers and/or load transfer devices, you can have confidence that the structure will be usable immediately following a disaster, so emergency vehicles, evacuation traffic etc. can continue to use the bridge. It is designed to allow both abutment and decks to move freely, and independently from each other.

Feel free to contact us to discuss your Finger Joint requirements. Our technical team are able to assist you with design specifications, installation recommendations and onsite inspections as needed. |